Dongguan Jingwei Optoelectronic Materials Co., Ltd.

0769-86362156

No.6 Tianxin Street, Yongkou Management District, Shijie Town, Dongguan City, Guangdong Province

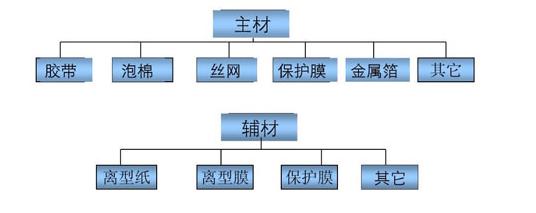

The picture above lists the main materials and auxiliary materials most commonly used in die-cutting factories. Let's talk about the foam in the main materials:

Polyurethane foam is also called polyurethane elastomer.

Polyurethane is an emerging organic polymer material and is known as the "fifth largest plastic". Because of its outstanding performance, it is widely used in many fields of the national economy.

Polyurethane elastomer is also called polyurethane rubber. It belongs to special synthetic rubber and contains more elastic polymers in the molecular chain (-NHCOO-) range. The raw materials are diverse, the formulas are diverse, and the adjustable range is large. The low-modulus rubber with a hardness as low as Shore A10 and the high-impact elastic material with a hardness as high as D85 (elastic modulus can be as high as several hundred MPa, while the elastic modulus of rubber The amount is 0.2~10MPa), so polyurethane elastomer is a polymer material ranging from rubber to plastic.

Foam is a high molecular polymer with many small cells, the solid phase is a polymer matrix, and the small cells are filled with gas.

The foam is divided into open and closed cells according to the structure of the cell. The cell connected with the cell is called the open cell structure, and the cell that is not connected with the cell is called the closed cell structure.

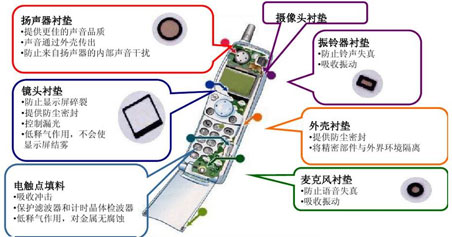

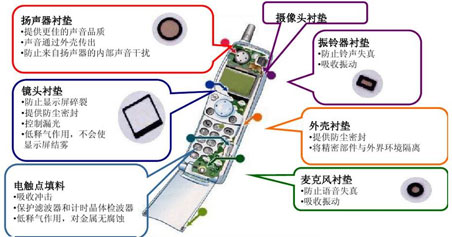

Example of application of polyurethane foam in mobile phone:

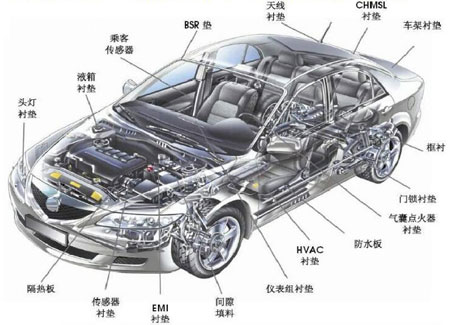

Application example of polyurethane foam in automobile:

Summary of the main uses of foam:

(1) Panel interlayer: function-no pollution, prevent loosening, prevent impact noise, prevent adhesion.

(2) Around the LED: prevent light leakage, absorb shock, and increase air tightness.

(3) Lower perimeter of PCB: absorb shock, absorb vibration, fill gaps, heat insulation effect.

(4) Keyboard gasket: rebound, no pollution, and good dimensional stability.

(5) Around the battery: no pollution, absorb impact sound, improve air tightness.

(6) Foot pads: good friction, no pollution, and good dimensional stability.

(7) Rear pad of disk drive: absorb vibration, prevent impact noise, and improve air tightness.

(8) Friction pads: good friction, no pollution, and good dimensional stability.

(9) Disk cover cushion: absorb vibration, block motor noise, prevent vibration and improve air tightness.

(10) Around the speaker: prevent noise and fill gaps.

(11) Around the LCD: Dustproof, absorb shock, fill gaps, improve shading.